Industrial Solutions

for Automated Productions

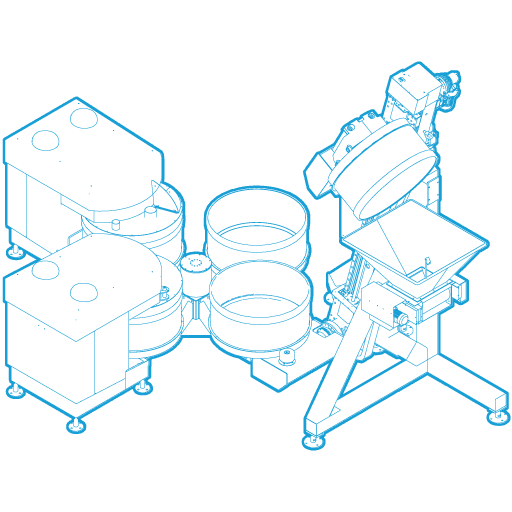

COMPLEX SYSTEMS

Very long fermenting time, with complex mixing cycle. Space-sacing solutions with multiple level Robots. Integration of multiple automatic mixing systems and technology to reproduce automatically your very special mixing process.

LIQUID FERMENT

Delicate handling system of liquid ferment. Available for wheat liquid ferment. Complete integration with mixing system. PH control of the liquid ferment. Easy and fast cleaning.

CONTINUOUS MIXER

The only continuous mixer with a scientifically constant dough quality control. Very high production rate. Flexibly (1 to 5) in production per hour and in mixing intensity.

ROBOT

Control of the dough quality through the complete mixing and resting process. Flexible recipe programming Very fast moving of the Robot for a very short cycle time. Space saving thanks to our innovative solutions.

CAROUSEL

Shorted cycle time, easy dosing of big ingredients, fully automatic. Very high production rate in a small footprint. Automatic washing of bowls and mixers available. Constant control of dough quality. Stress-free dumping of dough tanks to our patented EG Elevator/tilter.

BOTTOM DISCHARGE

Compact, efficient and cost saving automatic system. Easy sanitation (also automatic) with innovative, patented opening of the bowl for discharge. Available in multiple configurations according to the production needs. Constant control of dough quality.

Allied Bakery Equipment is the North American Importer, Distributor and Manufacturers Representative for Sancassiano, we also stock many parts for Sancassiano Equipment and Systems on the West Coast.

Sancassiano, a world leader in innovation and total automation of vertical mixing technologies, including: Robot Systems, Carousel Systems, and Continuous Mixing Systems. We can provide you with a specialized system to meet your needs for all types of mixes and batters. Whether you need systems for bagels, pizzas, breads, pies, pastries, cakes, biscuits, or a special batter or dough, we can customize a system for you. Along with our automated systems oriented to the industrial baking market we also carry a large line of mixing solutions for small and medium-size bakeries.

New Generation series of mixing systems with the following features:

Self supporting massive steel structures

Self supporting massive steel structures

High precision mono block mixing tools in stainless steel to increase consistency and repeatability of ready dough

OIL FREE Driving system for mixing tools and bowl (with easily removable seals for quick routine maintenance) to avoid contamination risks, and to reduce maintenance.

OIL FREE Driving system for mixing tools and bowl (with easily removable seals for quick routine maintenance) to avoid contamination risks, and to reduce maintenance.

Control of mixing tools speed by inverter for maximum flexibility

Mono block Mixing bowl in full stainless steel produced with high precision processes in order to guarantee consistency and repeatability of the dough

Mixing chamber with sanitary design without screws, crevices and areas with possible dirt accumulation.

Lid in stainless steel with labyrinth seal to respect ATEX norms for zone 22

Universal bowl hooking system for highest versatility. Same locking device to be used independently both in our stand alone Genesi mixers and in our automatic systems.

Possibility of a Low cost modification to change the mixing technology (Single Spiral, Double Spiral and Revo) at any time.

Possibility of a Low cost modification to change the mixing technology (Single Spiral, Double Spiral and Revo) at any time.

Mixer frame raised 120 mm off the ground with stainless steel feet and horizontal surfaces inclined by 3° to guarantee easiness of cleaning and sanitization.

Electric board IP 65 fixed to the right side of the mixer body.

GENESI range uses only:

- Food grade oil and lubrication

- High efficiency electric motors

Recipe programmer with 5.7” touch-screen panel with the following features:

- Possibility to program and store up to 20 recipes and 6 mixing phases per recipe

- Automatic and manual mode

- Request for manual ingredients addition (with the mixer head up or down) at the beginning of each phase.

- Display of the instantaneous power and the characteristic dough curve

- Display of the total and specific energy and its graph

- Active Protection of mechanical and electrical components

- Display of the the dough temperature (available with optional temperature sensor purchased separately) and related the graph

- Managements of alarms (codes and descriptions) not included.

- Graph customization and pre-programmed language choice (12 languages)

You must be logged in to post a comment.