Dough Processing

Showing all 4 results

-

Bakery Equipment

SANCASSIANO Bowl Elevator – Model ERT

-

Bakery Equipment

SANCASSIANO Double Arm Elevator – Model ER2

-

Bakery Equipment

SANCASSIANO One Arm Elevator – Model ER1 OB

-

Bakery Equipment

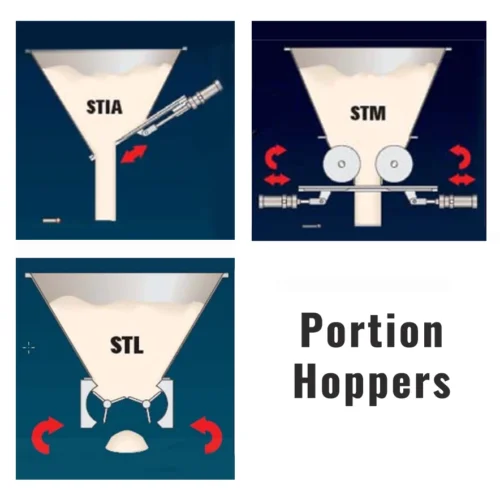

SANCASSIANO Portioning Hopper – Model STIA/STM/STL